Birla A1 Premium Cement “Concrete Xpert” – to ensure the best quality

“Concrete Xpert” is a unique service for our customers. Our highly experienced techno-marketing team will demonstrate, provide guidance and reassure you of the outstanding quality of Birla A1 Premium Cement right at your doorsteps. Our mobile Concrete Engineer Vans are equipped with sophisticated instruments to -

• Educate you on various ways to test the quality of cement used

• Provide onsite technical services to you through our expert Personnel

To avail of these services customer may call the following numbers:-

-

Sand

Silt Content Test using Measuring Glass Cylinder

Test to detect presence of impurities, dust and silt content in the fine aggregate ( river sand / manufactured sand). The maximum quantity of silt in sand should not exceed 8%. Fine aggregate containing more than 8% of silt should be washed so as to bring the silt content within allowable limits.

-

Aggregate

Thickness Gauge – Flakiness of Aggregate

This test is used to determine if aggregate particles are to be considered flaky. Right aggregate gives high quality concrete. Aggregate influences the properties of both fresh and hardened concrete and impacts the character and performance of the concrete mix.

Length Gauge – Elongation index of aggregates

This test determines the elongation index of aggregates. Aggregate particles are considered elongated when their length is more than 1.8 of their nominal size. Right aggregate gives high quality concrete.

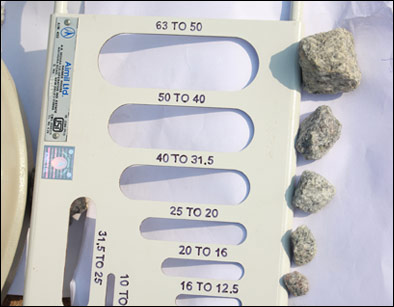

Sieve Analysis of Coarse Aggregate

This method includes sampling and determination of the gradation of coarse aggregate (Gravel). Well graded aggregate increases the workability of the concrete and avoids honeycombing.

Sieve Analysis of fine aggregate for particle size distribution

This method covers the sampling and determination of the particle size distribution of fine aggregates. Optimum particle size distribution increases the workability of the concrete & can avoid honeycombing.

-

Concrete

Compressive Testing Machine

Compressive Testing Machine is used to test the compressive strength of concrete at various ages.

1 Day3 Days7 DaysBIS StandardNA16 Mpa min22 Mpa minBirla A1 Premium Cement18+-2 Mpa30+-2 Mpa40+-2 MpaHow does it benefit you?Better initial strength resulting in faster deshutteringSlump Cone with Testing Rod & Base Plate

The test is carried out using a mould known as a slump cone. At sites it is performed by the Birla A1 Premium Cement technical team to check the consistency of freshly made concrete. The slumped concrete takes various shapes, and according to the profile of slumped concrete, the slump is termed as true slump, shear slump or collapse slump. Only the true slump indicates concrete can be used whereas a shear or collapse slump should be corrected and the test should be repeated.

-

Post-Construction Testing

Rebound Hammer

The device is used to measure the elastic properties or strength of concrete or rock, mainly surface hardness and penetration resistance.

-

Cement Testing

Cement Testing

Cement testing plays a vital role in ensuring quality control throughout the manufacturing process as well as before use in construction projects. Common tests conducted include:

- Fineness test

- Setting time test

- Compressive strength test

These tests help determine whether the cement meets required standards before being utilized in building projects. At Birla A1 Cement, we adhere strictly to testing protocols to ensure every batch meets industry benchmarks.

Learn more about our rigorous testing processes by visiting our website or contacting us directly!