Your dream home should last for generations

use the best quality Cement.

Self-Compacting Concrete – The future of concrete?

Self-Compacting concrete is a concrete that’s capable of flowing by its own weight and filling moulds with dense reinforcements without any external compaction effort, still maintaining its homogeneity without separation of its different components.

Self Compacting Concrete

The problem of durability of concrete structures was a major topic of interest in Japan. The gradual reduction in the number of skilled workers in Japan’s construction industry has led to a similar reduction in the quality of construction. The solution for achieving this structure is employment of self-compacting concrete, which can be compacted to every corner of the framework by its own weight .The prototype of self-compacting concrete was completed in 1988 under the name of ‘High Performance Concrete’ and was defined at three stages:

- 1) Fresh: Self-Compactable

- 2) Early Age: Avoidance of Initial Defects

- 3) After Hardening : Protection against external Factors

The method for achieving self-compatibility is through resistance to segregation between coarse aggregate and mortar when the concrete flows through the confined zone of reinforcing bars .The following methods are used to achieve self-compactibility.

- 1. Limited Aggregate Content – The frequency of collision increases as the relative distance between particles decreases and then internal stress increases. Limiting the coarse aggregate content to a level lower than normal is effective in avoiding this kind of blockage.

- 2. Low water-powder ratio – High viscous paste is required to avoid the blockage of coarse aggregate, when concrete flows through obstacles.

- 3. Use of VRA (Viscosity Reduction Agents) – High deformability can be achieved by the employment of VRA keeping water powder ratio to very low value.

Self Compacting Concrete

Normal Concrete

There are three purposes for self-compactibility tests relating to practical purpose:

- 1) To check whether or not the concrete is self-compactable for the structure This is done through U-flow test. In this test, the degree of compactability can be indicated by the height that the concrete reaches after flowing through an obstacle.

- 2)To adjust the mix proportion when self-compactibility is not sufficient Slump Flow tests and Funnel tests have been proposed for testing deformability and viscosity

- 3) To characterize materials Flow and Funnel tests for mortar have been proposed to characterize materials used in self-compacting concrete.

In order for self-compacting concrete to be used as standard concrete, new systems of design, manufacturing and construction has been established. Currently, 70% of concrete is produced by the ready-mixed concrete industry in Japan.

APPLICATIONS OF SELF-COMPACTING CONCRETE IN JAPAN:The main areas for employment of self-compacting concrete are:

- 1) Bridges

- 2) Box Culverts

- 3) Concrete filled steel columns

- 4) Tunnels

- 5) Dams

Reasons for employing self-compacting concrete:

- 1) To shorten construction period

- 2) To assure compaction

- 3) To eliminate noise due to vibration

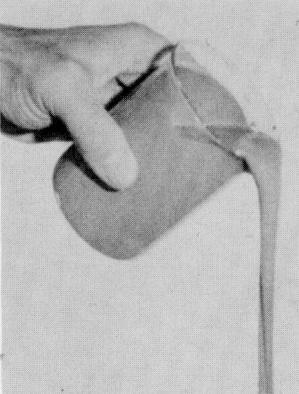

Self Compacting Concrete being used at a construction site

Though main obstacles in the use of self-compacting concrete have been largely solved, rapid diffusion of technology is largely required for production of self-compacting concrete. In addition, new structural designs and construction systems making full use of self-compacting concrete should be introduced.

For better results always use good quality sand in the right proportion with Birla A1 Premium Cement to ensure a cohesive concrete mix. And watch our 2 minute video on the importance of sand so that you can have a Happy Home Building!

Back

Back